Invisible waste explained in 500 words

- Science-by-Trianon

- Nov 20, 2020

- 2 min read

Updated: Apr 10, 2021

The European Week for Waste Reduction starts tomorrow, November 21st, 2020.[1]

One of the issues raised is that of invisible waste.

But what is it? How can we reduce them?

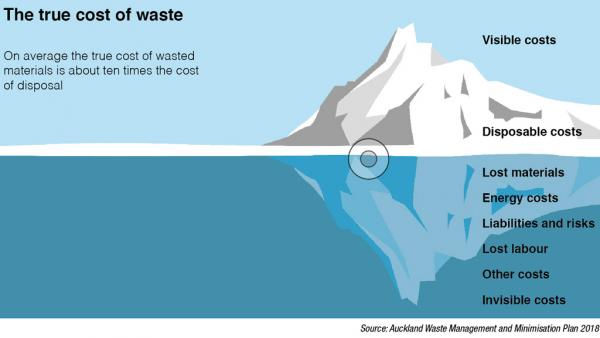

The now-common example for invisible waste is that producing a mobile telephone weighing less than 200 g generates more than 80 kg of waste — an iceberg model.

The iceberg model

The chemical industry has known this concept for some 30 years by now, when Roger Sheldon introduced the “E-factor”. [2]

Put simply, it relates the mass of the chemical products produced to the mass of the starting materials used in the process.

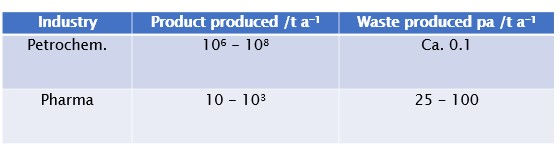

This led to the perhaps counter-intuitive insight that the pharmaceutical industry with its “clean” image of white coats, shining laboratories, and healing products is, in fact, much more dirty than the petrochemical industry with its “dirty” image of smoking refineries, massive open pit coal mines, and greasy oil rigs spilling crude oil into the sea.

In absolute terms, the petrochemical industry produces much more waste than the pharmaceutical industry.

However, in relative terms the pharmaceutical industry is far less efficient and atom-economic than the petrochemical one.

The following table may illustrate this point:

Even in the world of chemistry, the E-factor alone does not say much about how environmentally benign a process is (or not).

As a matter of fact, a less favourable E-factor for Process X may be counterbalanced by using less harmful starting materials and/or auxiliaries, and various ways of expressing such considerations have been proposed.[3][4]

Applied to the mobile telephone given as an example in the beginning of this article, the E-factor turns out to be 400, an extraordinarily high number, however, it must be kept in mind that this includes steps like extracting metals from ores.

Mobile phone's life cycle

Obviously, manufacturing a complex piece of technology cannot be compared to a relatively simple chemical reaction, however, it gives an insight into the efficiency of industrial processes (or lack thereof).

Processes like extracting metals from ores cannot be made much more efficient in terms of their E-factor because here the E-factor is given by the metal content in the ore.

What can (and should!) be addressed is the process in which the metal is extracted from its ore (cf. gold leaching with cyanide [5]).

On the other hand, metals can be extracted from waste electric and electronic equipment. [6]

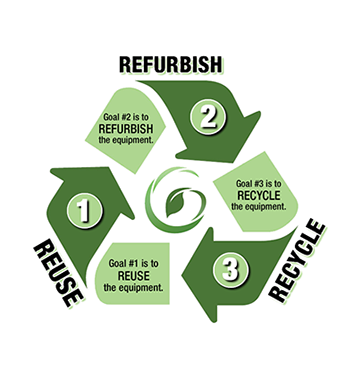

The key to reducing the invisible waste is reusing, repairing, refurbishing, and recycling, because any piece of equipment carries its burden of invisible waste.

However, if that piece of equipment is used, repaired, and eventually recycled no second piece of equipment has to be produced.

Comments